Ever wonder how products move seamlessly across borders and arrive in bulk to retailers, distributors, or foodservice operators so quickly? The answer lies in fulfillment services, powered by logistics experts who manage the process from warehouse to delivery.

At McLane Global, our fulfillment solutions allow manufacturers and brands to focus on growth while we handle the warehousing, logistics, and operational complexity behind the scenes. The following guide illustrates what fulfillment services are, what they entail, why they are important, how you can select the right partner, and how to ensure your fulfillment strategy is the right foundation for a successful future.

Defining Fulfillment: From Manufacturer to Customer

For manufacturers and brands, fulfillment is more than storage and shipping. It’s the link that ensures products move from production floors to distribution centers and retail shelves efficiently and accurately.

The Core Stages of Fulfillment

Fulfillment can be broken down into six interconnected functions that keep operations moving:

Inventory Management:

Inventory Management:

Monitoring and controlling stock levels to avoid shortages or overages.

Warehouse & Storage:

Warehouse & Storage:

Providing secure, organized space for products until they’re needed.

Receiving:

Receiving:

Accepting and checking inbound goods from manufacturers or suppliers.

Pick & Pack:

Pick & Pack:

Preparing the right items in the right quantities for shipment.

Shipping:

Shipping:

Coordinating carrier networks to move products efficiently.

Returns:

Returns:

Managing reverse logistics, from restocking to replacements.

Together, these stages form the backbone of fulfillment; ensuring that orders flow smoothly, and clients receive what they need, when they need it.

Why Fulfillment Services Matter Today

Meeting Customer Expectations

Meeting Customer Expectations

In B2B, delivery expectations revolve around precision and reliability. Retailers and distributors expect accurate bulk shipments, real-time tracking, and efficient returns handling. 3PLs with multiple strategically located warehouses can reduce lead times and increase service consistency across regions.

Scalable Warehouse Space

Scalable Warehouse Space

Internal operations can be strained during seasons of growth or spikes. A committed 3PL warehouse takes up the load and grows with your business without the need to invest in extra staff, warehousing, or sellers. It implies that there would be no sales loss in the peak season or SKU growth.

Expanding Global Reach

Expanding Global Reach

A 3PL partner provides expertise in new markets, from customs compliance to local distribution networks, making international expansion faster.

Cost Efficiency

Cost Efficiency

With 3PLs, you avoid fixed overhead. Instead, you pay for space, labor, and shipping as you use them; creating a more flexible and scalable cost model.

The Order Fulfillment Process Explained

Knowing where your products go between creation and delivery is the first step in streamlining operations, reducing delays, and improving customer satisfaction.

The following scenario will give you an idea of how a product generally travels through the supply chain until it is in your customer’s hands.

Manufacturing the Product

Manufacturing the Product

The process begins when the manufacturer produces finished goods in bulk, anticipating demand from distributors, wholesalers, or retailers.

Distributor or Retailer places a Purchase Order

Distributor or Retailer places a Purchase Order

A distributor, wholesaler, or retail partner submits a purchase order (PO) to the manufacturer or fulfillment provider.

Preparing for Shipment to the Wholesaler

Preparing for Shipment to the Wholesaler

Once the PO is confirmed, the manufacturer releases goods to a freight carrier for delivery to a warehouse or fulfillment center.

Transportation to Fulfillment Center

Transportation to Fulfillment Center

Products are shipped by truck, rail, air, or ocean freight, depending on the distance and urgency. Transit time may range from a few days for domestic shipments to several weeks for international ocean freight.

Receiving & Storage at Fulfillment Center

Receiving & Storage at Fulfillment Center

Once the shipment comes, the wholesaler revisits records on inventory systems so that the retailers know what they have to offer.

Retailer, Distributor, or Foodservice Client Requests

Retailer, Distributor, or Foodservice Client Requests

Goods arrive at the fulfillment center, where they are inspected, checked into inventory systems, and stored until orders are scheduled for fulfillment.

Order Processing, Pick & Pack

Order Processing, Pick & Pack

The wholesaler finds the product in storage, packs it safely, and delivers it to the shipping carrier to be delivered to the end destination.

Carrier Coordination

Carrier Coordination

Fulfillment staff hand orders over to freight carriers, coordinating the appropriate mode (LTL, FTL, parcel, or international freight).

Shipment

Shipment

Orders are transported domestically or internationally, with transit times based on service level and carrier type. Tracking information is generated and shared with the client.

Delivery to Retailer, Distributor, or End-Customer

Delivery to Retailer, Distributor, or End-Customer

The final delivery completes the process. Products arrive at the designated distribution center, retail shelf, or foodservice facility, ready for sale or use.

Differentiators: Choosing Your 3PL Partner

Instead of some generic checklists, the following are some important considerations to note:

Technology: Visibility Is Critical

Technology: Visibility Is Critical

Ensure that your 3PL warehouse executes a real-time dashboard and integrates with your sales site via an API. This permits immediate updates in terms of inventory levels, orders, and shipping metrics, keeping your team up-to-date and responsive.

Tech Support and Customization

Tech Support and Customization

Only adaptable partners work with brands that have subscription models, special-box packaging, or bundle products. Make sure your 3PL third-party logistics vendor can support customized processes, custom packaging, and promo inserts.

Operational Scale

Operational Scale

When you are expanding to a new country, ensure that it possesses scalabable facilities around the major distribution centers and a robust carrier network.

Service Levels and Performance Indicators

Service Levels and Performance Indicators

The industry’s fulfillment accuracy currently averages 99%+, yet your customers desire more. Speak about throughput capacity, average fulfillment time, and contingency readiness.

Regulated Products Compliance

Regulated Products Compliance

When you ship food, medical supplies, or electronics, you require a different kind of service provider, one that knows how to work with temperature, lot tracking, and FDA requirements. A certified logistics company makes sure that it follows the regulations at each step.

Integrations and Technology

Best 3PL third-party logistics players become integrated into your systems:

- E-commerce services: Shopify, BigCommerce, WooCommerce

- Marketplaces: Amazon Seller Central, Walmart Marketplace

- Orders: ShipStation, ShipBob, Channel Advisor

- ERP/WMS systems: Oracle, NetSuite, Microsoft Dynamics

These interconnections simplify all processes, including uploading orders to real-time tracking, decreasing the level of manual handling, and increasing accuracy.

Fulfillment Services Across Industries

Every industry has gratification challenges, and the best 3PL third-party logistics companies are prepared to handle them. To make an example,

Food & Beverage:

Food & Beverage:

The food and beverage industry may demand the presence of temperature-controlled environments and adherence to an inventory rotation, following the expiration dates.

Beauty & Personal Care:

Beauty & Personal Care:

Beauty and personal care: Beauty brands pay great attention to presentation, require special packaging, and are sensitive to handling fragile products.

Electronics:

Electronics:

Electronics producers require anti-static packaging, exquisite lot administration, and safe serial number reporting to fulfill warranty and compliance needs.

Fashion:

Fashion:

High SKU variation and return-friendly systems that could effectively undertake exchanges might require fashion and apparel companies to support them.

Subscription Box:

Subscription Box:

Kitting capabilities can help subscription box companies assemble many SKUs into branded curated packages with branded inserts and promotional material.

Whatever industry you are in, McLane Global is a qualified full service logistics warehouse that provides configurable workflow, compliance expertise, as well as value-added services that fit alongside the operational peculiarities of every product type.

Final Thoughts

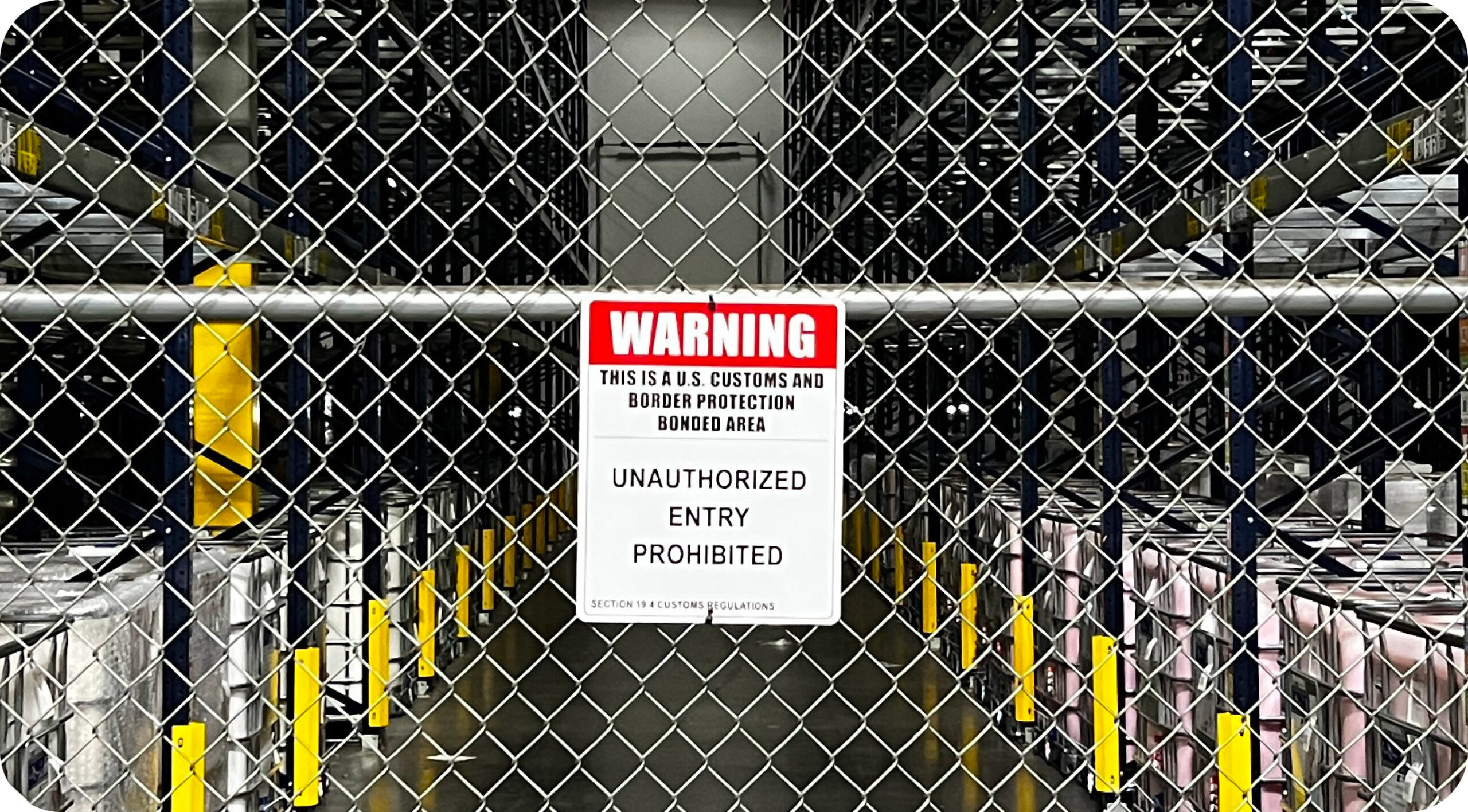

We can help you improve your order fulfillment and supply chain in a number of beneficial ways. With McLane Global’s FTZ and Customs-Bonded Warehouses, integrated fulfillment centers, and over a century of logistics expertise, we help businesses streamline operations, cut costs, and scale with confidence.

FAQ

Frequently Asked Questions

A 3PL will provide all levels of logistics-based services, warehousing and freight, and the fulfillment center, in its most basic form, is all about picking, packing, shipping, and returning. Practically, many partners have overlapping services.

Yes, entry costs are low, and even minor brands can enjoy cost savings and quicker delivery as part of outsourcing fulfillment.

Absolutely. The top third-party logistics companies are integrated with Shopify, WooCommerce, Amazon, and ERP, making order and inventory management automatic.

Most of them have regional ready-to-peak labor pools and storage space. Simply give them advance forecasts of demand.

High performers are more than 99% accurate with barcode scanning, using sophisticated WMS, and training personnel.

Yes, when you have an FDA-registered warehouse with a temperature-regulated area to store perishable and non-perishable items.

Well, yes, lots of them have global fulfillment centers. They will take care of customs compliance, duties, and last-mile deliveries.

Assess their technology, geographical coverage, pricing, customer care, and product placement with your product category.

Yes, onboarding can be seamless, including receiving, integrations, and first shipments with clean inventory and clear forecasts.

How the Role of

In today’s market, businesses of all sizes face intense pressure to deliver faster, operate more efficiently, and maintain...

Read a full articleWhat are Fulfillment Services,

Ever wonder how products move seamlessly across borders and arrive in bulk to retailers, distributors, or foodservice operators...

Read a full articleWhat Is the Difference

What if you could save millions on duties just by choosing the right logistics strategy? With externally found...

Read a full article